close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

| Parameter | Value |

|---|---|

| Origin | Wuxi, China |

| Brand | Wuxi Triumph Gases Equipment |

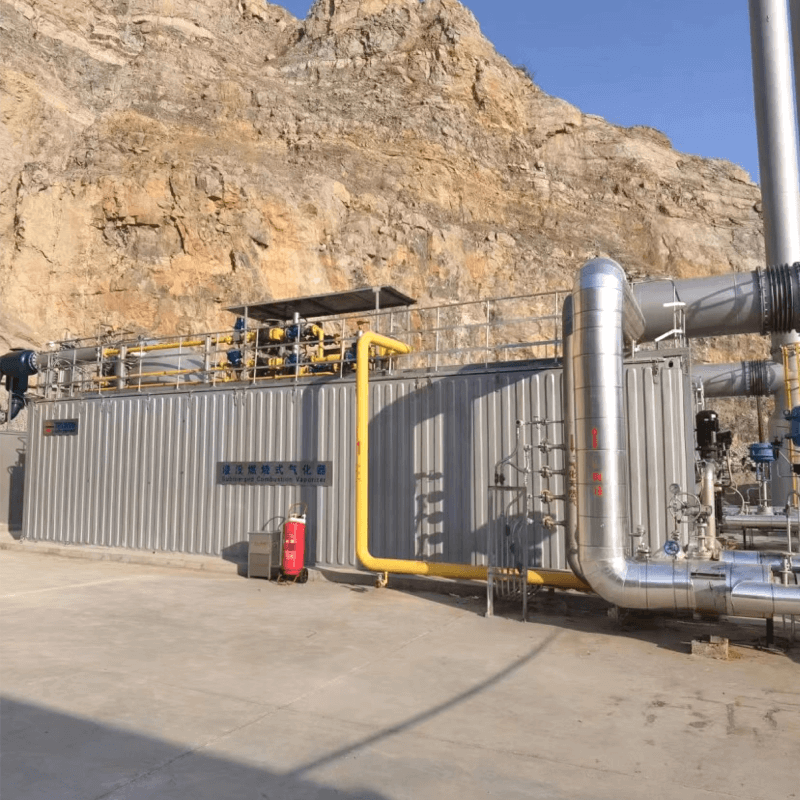

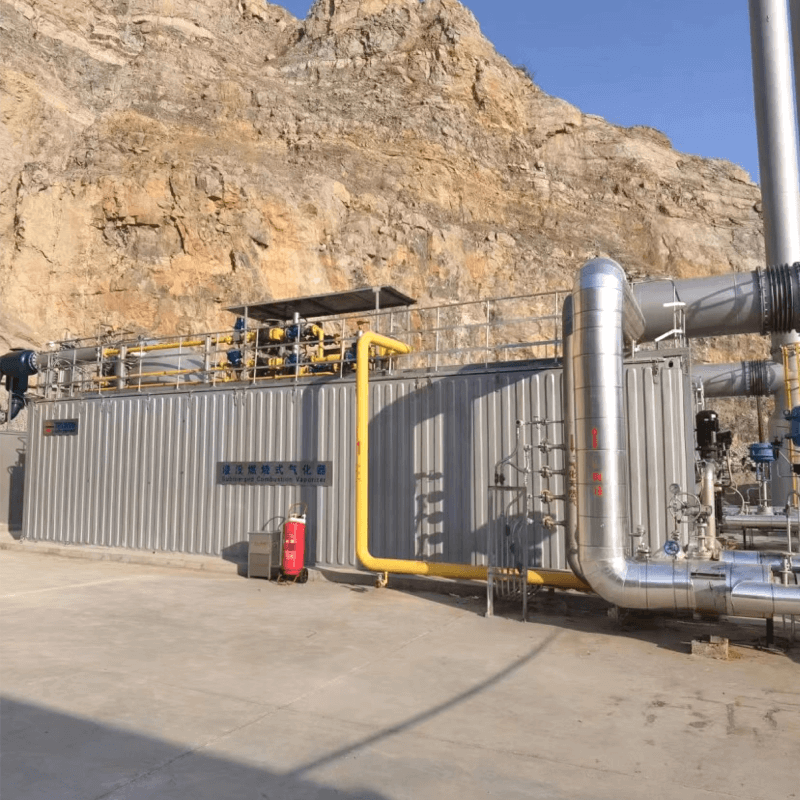

| Product Name | Submerged Combustion Vaporizer (SCV) |

| Gasification Medium | LNG, Other Cryogenic Media |

| Gasification Capacity | 10% - 110% (Adjustable) |

| Heat Exchange Efficiency | Very High |

The Submerged Combustion Vaporizer (SCV) is a high-performance solution designed for large-scale LNG vaporization in import terminals, peak shaving stations, and industrial gas plants. Unlike indirect heat exchange methods (such as intermediate fluid vaporizers), SCV employs a direct combustion system where burner exhaust gases are submerged into a water bath, transferring heat to LNG through submerged tube coils made of 316L stainless steel. This direct heat transfer design delivers vaporization rates up to 200 t/h with 98% thermal efficiency, making it ideal for applications requiring rapid load response (e.g., sudden grid demand spikes) and minimal environmental impact .

Ultra-High Thermal Efficiency

Achieves 98% heat transfer efficiency by directly transferring combustion heat to the water bath, outperforming traditional open rack vaporizers (ORVs) by 10–15% in energy utilization .

Handles sudden load changes with a turndown ratio up to 1:10 (e.g., from 200 t/h to 20 t/h) without thermal stress, ensuring stable operation during peak demand periods .

Compact and Modular Design

Skid-mounted configuration reduces footprint by 40% compared to ORVs, with a typical 100 t/h unit requiring only 20–30 m² of installation space—ideal for space-constrained terminals or retrofitted sites .

Modular burners allow incremental capacity expansion (e.g., adding 2–4 burners to increase output from 50,000 to 200,000 Nm³/h) without major system overhauls.

Low-Emission and Safe Operation

Equipped with low-NOx burners (≤40 ppm) featuring staged combustion technology, compliant with strict environmental regulations such as the EU Industrial Emissions Directive and US EPA standards .

Dual-leak detection (hydrocarbon sensors with 0–100% LEL range and pressure transmitters) triggers immediate shutdown within 2 seconds of LNG or water leaks, preventing safety hazards.

LNG Terminals: Primary vaporization for import facilities, supporting continuous base load operations (e.g., 24/7 LNG unloading from carriers with 150,000 m³ capacity).

Peak Shaving Stations: Rapid vaporization during winter demand spikes, maintaining grid stability (e.g., reaching 100,000 Nm³/h within 15 minutes of startup).

Industrial Gas Plants: Vaporization of cryogenic liquids beyond LNG, including liquid oxygen (for steel mills) and liquid ethylene (for petrochemical polymerization processes).

Q: How is combustion exhaust treated to meet emission standards?

A: SCV uses low-NOx burners with premixed air-gas ratios (1:10 to 1:15) to reduce thermal NOx formation. For regions with stricter limits (e.g., California Air Resources Board), a selective catalytic reduction (SCR) system can be integrated, lowering NOx to ≤5 ppm using urea injection .

Q: What maintenance is required for SCV?

A: Routine checks include water bath pH monitoring (maintained at 8–9 with sodium carbonate to prevent coil corrosion) and burner nozzle inspection (cleaned quarterly to remove carbon deposits). Annual water quality testing ensures no scaling in the bath .

Q: Can SCV handle LNG with high nitrogen content?

A: Yes. SCV’s water bath maintains a constant temperature buffer (60–80°C), ensuring stable vaporization even for LNG with nitrogen content up to 5%—common in certain regional LNG supplies .

| Parameter | Value |

|---|---|

| Origin | Wuxi, China |

| Brand | Wuxi Triumph Gases Equipment |

| Product Name | Submerged Combustion Vaporizer (SCV) |

| Gasification Medium | LNG, Other Cryogenic Media |

| Gasification Capacity | 10% - 110% (Adjustable) |

| Heat Exchange Efficiency | Very High |

The Submerged Combustion Vaporizer (SCV) is a high-performance solution designed for large-scale LNG vaporization in import terminals, peak shaving stations, and industrial gas plants. Unlike indirect heat exchange methods (such as intermediate fluid vaporizers), SCV employs a direct combustion system where burner exhaust gases are submerged into a water bath, transferring heat to LNG through submerged tube coils made of 316L stainless steel. This direct heat transfer design delivers vaporization rates up to 200 t/h with 98% thermal efficiency, making it ideal for applications requiring rapid load response (e.g., sudden grid demand spikes) and minimal environmental impact .

Ultra-High Thermal Efficiency

Achieves 98% heat transfer efficiency by directly transferring combustion heat to the water bath, outperforming traditional open rack vaporizers (ORVs) by 10–15% in energy utilization .

Handles sudden load changes with a turndown ratio up to 1:10 (e.g., from 200 t/h to 20 t/h) without thermal stress, ensuring stable operation during peak demand periods .

Compact and Modular Design

Skid-mounted configuration reduces footprint by 40% compared to ORVs, with a typical 100 t/h unit requiring only 20–30 m² of installation space—ideal for space-constrained terminals or retrofitted sites .

Modular burners allow incremental capacity expansion (e.g., adding 2–4 burners to increase output from 50,000 to 200,000 Nm³/h) without major system overhauls.

Low-Emission and Safe Operation

Equipped with low-NOx burners (≤40 ppm) featuring staged combustion technology, compliant with strict environmental regulations such as the EU Industrial Emissions Directive and US EPA standards .

Dual-leak detection (hydrocarbon sensors with 0–100% LEL range and pressure transmitters) triggers immediate shutdown within 2 seconds of LNG or water leaks, preventing safety hazards.

LNG Terminals: Primary vaporization for import facilities, supporting continuous base load operations (e.g., 24/7 LNG unloading from carriers with 150,000 m³ capacity).

Peak Shaving Stations: Rapid vaporization during winter demand spikes, maintaining grid stability (e.g., reaching 100,000 Nm³/h within 15 minutes of startup).

Industrial Gas Plants: Vaporization of cryogenic liquids beyond LNG, including liquid oxygen (for steel mills) and liquid ethylene (for petrochemical polymerization processes).

Q: How is combustion exhaust treated to meet emission standards?

A: SCV uses low-NOx burners with premixed air-gas ratios (1:10 to 1:15) to reduce thermal NOx formation. For regions with stricter limits (e.g., California Air Resources Board), a selective catalytic reduction (SCR) system can be integrated, lowering NOx to ≤5 ppm using urea injection .

Q: What maintenance is required for SCV?

A: Routine checks include water bath pH monitoring (maintained at 8–9 with sodium carbonate to prevent coil corrosion) and burner nozzle inspection (cleaned quarterly to remove carbon deposits). Annual water quality testing ensures no scaling in the bath .

Q: Can SCV handle LNG with high nitrogen content?

A: Yes. SCV’s water bath maintains a constant temperature buffer (60–80°C), ensuring stable vaporization even for LNG with nitrogen content up to 5%—common in certain regional LNG supplies .